ICM Makes Food And Ethanol

#1

ICM, the fuelmaker is adding a process that will make oil and protein for human consumption as part of ethanol production.

BY PHYLLIS JACOBS GRIEKSPOOR

The Wichita Eagle

ICM, the Colwich-based designer of ethanol plants, is introducing a new process that will allow ethanol plants to produce high-quality human and animal food -- in addition to biofuel -- from corn.

The new technology, developed over a decade of research at ICM plants in Colwich and St. Joseph, Mo., adds new product lines to the ethanol production process while reducing the consumption of fossil fuels, enzymes and water, said David Vander Griend, president of ICM.

The process -- called Total Kernel Optimization or TKO -- will be unveiled Monday at the International Fuel Ethanol Workshop in Nashville.

"The ethanol plants of tomorrow will probably make more money from selling human food products than from selling fuel," Vander Griend said.

Installation of the technology has already begun at the St. Joseph plant, which ICM owns jointly with Lifeline Foods. Snack grits, a ground product used to make snacks for human consumption, are already manufactured at that plant.

"Sometime down the road is the stand-alone cellulosic plant that will make ethanol from waste wood scraps and biomass," Vander Griend said.

"But we can't afford to wait that long to improve the industry's productivity and profitability. We had planned to roll this out next year... but the industry needs it sooner. So we're delivering it sooner."

Vander Griend said the new technology will make ethanol profitable, even if gasoline prices fall and corn continues to sell for $6 to $7 a bushel. That's because the new process produces items -- such as corn oil and high-protein concentrate -- worth more than $4 a pound.

In addition, costs for natural gas can be reduced -- by up to 80 percent -- by burning a fuel derived from the production process.

Vander Griend said increasing the value derived from processing is more important than reducing the price of corn.

"Frankly we need corn at $5 of $6 for American farmers to be profitable and for agriculture in Third World countries to become established," he said.

The new process

The new process can be installed in an operating ethanol plant without interrupting current production, Vander Griend said. Paying for the upgrade by using revenue from increased product lines is expected to take 18 to 24 months.

The new process is "dry mill" or "dry fractionation" as opposed to the current "wet milling" process that produces human food such as corn oil, corn starch and high fructose corn syrup; ethanol, and distillers grain for animal feed.

It more fully separates the components of the corn kernel to create germ, endosperm and fiber.

From the germ, oil and protein are harvested for the human food market.

The endosperm provides starch and protein. The starch becomes ethanol and the protein is human food.

The fiber from both becomes fuel to power the plant.

Vander Griend said the retrofit of the St. Joseph plant will be completed in two to three years. ICM has a goal of retrofitting nine existing plants a year, beginning in 2009.

About 50 percent of existing ethanol production facilities use ICM's process. That includes 73 operating plants and 26 under construction.

But the building pace for new plants has slowed drastically. ICM has not started a new construction project in almost a year.

The industry slowdown has come from a combination of factors including a glut of ethanol caused by production that outpaced the ability to transport and blend it. Higher construction costs, higher corn costs and a nationwide credit crunch also are factors.

That's the advantage of the new process, which produces food in addition to fuel. The process also has other advantages.

"The world food system has been long on starch and short on protein for decades," Vander Griend said. "The plant proteins created in this process can be sold to supplement the diets of humans in developing countries or fed to livestock to produce meat in other parts of the world."

The separation of oil and fiber from the protein also will create a higher-quality distillers grain that will be suitable to use in feeding swine and poultry as well as the cattle feed it currently provides.

"The lower-cost protein supplements gained in this process retain the human- and animal-food value of lower-priced corn to producers," Vander Griend said. "At the same time, it produces the biofuel that has already dropped gasoline prices by 10 to 15 percent over where they would be without ethanol."

http://www.kansas.com/101/story/435098.html

http://www.whatdoesenergymeantoicm.c...yInterior.html

http://www.icminc.com/

BY PHYLLIS JACOBS GRIEKSPOOR

The Wichita Eagle

ICM, the Colwich-based designer of ethanol plants, is introducing a new process that will allow ethanol plants to produce high-quality human and animal food -- in addition to biofuel -- from corn.

The new technology, developed over a decade of research at ICM plants in Colwich and St. Joseph, Mo., adds new product lines to the ethanol production process while reducing the consumption of fossil fuels, enzymes and water, said David Vander Griend, president of ICM.

The process -- called Total Kernel Optimization or TKO -- will be unveiled Monday at the International Fuel Ethanol Workshop in Nashville.

"The ethanol plants of tomorrow will probably make more money from selling human food products than from selling fuel," Vander Griend said.

Installation of the technology has already begun at the St. Joseph plant, which ICM owns jointly with Lifeline Foods. Snack grits, a ground product used to make snacks for human consumption, are already manufactured at that plant.

"Sometime down the road is the stand-alone cellulosic plant that will make ethanol from waste wood scraps and biomass," Vander Griend said.

"But we can't afford to wait that long to improve the industry's productivity and profitability. We had planned to roll this out next year... but the industry needs it sooner. So we're delivering it sooner."

Vander Griend said the new technology will make ethanol profitable, even if gasoline prices fall and corn continues to sell for $6 to $7 a bushel. That's because the new process produces items -- such as corn oil and high-protein concentrate -- worth more than $4 a pound.

In addition, costs for natural gas can be reduced -- by up to 80 percent -- by burning a fuel derived from the production process.

Vander Griend said increasing the value derived from processing is more important than reducing the price of corn.

"Frankly we need corn at $5 of $6 for American farmers to be profitable and for agriculture in Third World countries to become established," he said.

The new process

The new process can be installed in an operating ethanol plant without interrupting current production, Vander Griend said. Paying for the upgrade by using revenue from increased product lines is expected to take 18 to 24 months.

The new process is "dry mill" or "dry fractionation" as opposed to the current "wet milling" process that produces human food such as corn oil, corn starch and high fructose corn syrup; ethanol, and distillers grain for animal feed.

It more fully separates the components of the corn kernel to create germ, endosperm and fiber.

From the germ, oil and protein are harvested for the human food market.

The endosperm provides starch and protein. The starch becomes ethanol and the protein is human food.

The fiber from both becomes fuel to power the plant.

Vander Griend said the retrofit of the St. Joseph plant will be completed in two to three years. ICM has a goal of retrofitting nine existing plants a year, beginning in 2009.

About 50 percent of existing ethanol production facilities use ICM's process. That includes 73 operating plants and 26 under construction.

But the building pace for new plants has slowed drastically. ICM has not started a new construction project in almost a year.

The industry slowdown has come from a combination of factors including a glut of ethanol caused by production that outpaced the ability to transport and blend it. Higher construction costs, higher corn costs and a nationwide credit crunch also are factors.

That's the advantage of the new process, which produces food in addition to fuel. The process also has other advantages.

"The world food system has been long on starch and short on protein for decades," Vander Griend said. "The plant proteins created in this process can be sold to supplement the diets of humans in developing countries or fed to livestock to produce meat in other parts of the world."

The separation of oil and fiber from the protein also will create a higher-quality distillers grain that will be suitable to use in feeding swine and poultry as well as the cattle feed it currently provides.

"The lower-cost protein supplements gained in this process retain the human- and animal-food value of lower-priced corn to producers," Vander Griend said. "At the same time, it produces the biofuel that has already dropped gasoline prices by 10 to 15 percent over where they would be without ethanol."

http://www.kansas.com/101/story/435098.html

http://www.whatdoesenergymeantoicm.c...yInterior.html

http://www.icminc.com/

#3

FOR IMMEDIATE RELEASE

ICM, Inc. Guarantees Food AND Fuel Production in 2010

Biorefineries Investing in New Technology Able to Commercially Produce in Two Years

COLWICH, Kan. – June 16, 2008 – ICM, Inc. today announced that ethanol biorefineries

investing in the company's new, proprietary and innovative technology before the end of

this year, will be capable of commercially producing both food and fuel in 2010. The

announcement was made during ICM’s customer meeting at the annual Fuel Ethanol

Workshop (FEW) in Nashville, Tenn.

“We are talking about the ‘ethanol biorefinery of the future’…and very near future at that,”

said Dave Vander Griend, founder, president and CEO. “Fifty years ago, the U.S. fed the

world. We will be able to do that again with a food supply brought about by the evolution of

ethanol production.”

Since the company’s founding, ICM’s mission has been to sustain agriculture through

innovation. Recently, the company’s mission expanded to researching ways to deliver

much-needed protein to the world, by way of ethanol processing. At the same time, the

corn-to-ethanol industry is maturing, and a changing economic outlook is prompting

existing biorefineries to explore means of maintaining financial success in challenging tightethanol,

high-corn price markets. ICM recognized this changing outlook and is delivering on

its mission by developing technology to create "new renewables" that can be built upon the

existing ethanol biorefinery – the key facilitator of the new technology is a process called

dry fractionation.

Vander Griend says dry fractionation, the first component of ICM’s new six-part Food AND

FuelTM technology package, can be installed as early as the fourth quarter of this year, with

production coming on line in the second quarter of 2009.

After cleaning and moisture conditioning, the proprietary dry fractionation process

mechanically separates the corn kernel into its three main components: endosperm (the

starchy portion comprising most of the inner kernel), germ (the protein- and oil-rich center)

and bran (the kernel’s fibrous outer layer). More than just producing ethanol, optimizing

the whole kernel in this way allows for the production of a host of food-grade and feedgrade

co-products, as well as another alternate fuel source to power the process.

In addition to new food-processing capabilities, ICM’s new technology offering also provides

several other advantages for biorefineries:

• a guaranteed increase in ethanol production capacity

• reduced natural gas consumption

• decreased enzyme usage

• a platform for emerging technologies

• a bridge to cellulosic ethanol

ICM installed their first Food AND FuelTM technology package at a biorefinery in St. Joseph,

Mo. This facility, LifeLine Foods, is the proving ground for ICM’s “ethanol biorefinery of the

future” package, which includes the technology to transform corn fiber to cellulosic ethanol.

“Our situation is a little different than that of the typical ICM customer because we were a

food processor first,” says Mike Sobetski, vice president and COO, LifeLine Foods. “Prior to

partnering with ICM, more than 70 percent of our revenue came from food production. Coproducts

such as livestock feed and germ accounted for the remaining nearly 30 percent.

Today, two-thirds of our revenue is generated by ethanol and its co-products, and higherquality

food products comprise the remaining one-third. Even with this shift, we are

generating more revenue from the-now-30-percent food production than we were with 70

percent because of the increased capacities and the synergies of the new processes brought

to us by ICM.”

Based on the implementation and output happening at LifeLine, ICM has created a

preliminary economic model to outline the adoption of the new six-part Food AND FuelTM

technology package. By opening new markets for various co-products, there is the potential

for $1 billion in additional revenue over 10 years.

“We have always believed that ethanol is part of the solution to our economic, energy and

environmental issues and this is what we are doing to make ethanol better. We can now

make food during the ethanol process, we can process ethanol in an efficient and more

environmentally-friendly way, and we can help retain more of our energy dollars in the U.S.

while creating new markets for diversified global agriculture” said Vander Griend.

About Ethanol and Ethanol Processing

Ethanol is commercially produced in one of two ways, using either the wet mill or dry mill

process. Wet milling involves separating the grain kernel into its component parts (fiber,

protein, and starch) prior to fermentation. ICM-designed plants utilize a proprietary dry mill

process, where the entire grain kernel is ground into flour. The starch in the flour is

converted to ethanol during the fermentation process, while also producing carbon dioxide

and dried distillers grains (DDGS) as co-products. The carbon dioxide can be captured

(where economics allow) so it can be marketed to the food processing industry for use in

carbonated beverages and flash-freezing applications. Distillers grains are a valuable

livestock feed.

Ethanol is delivering on its promise as a renewable fuel. It is good for American vehicles, it

is good for the environment and it is good for the American economy.

• Environment. Ethanol is a clean-burning, renewable fuel. E85, a blend of 85 percent

ethanol and 15 percent gasoline, is the cleanest burning fuel available on the market

today. The use of gasoline enriched with 10 percent ethanol, E10, reduces

greenhouse gas emissions by 12 to 19 percent compared with conventional gasoline,

according to Argonne National Laboratory. E10 also reduces carbon monoxide

emissions by as much as 30 percent

• Economy. Ethanol is blended into nearly 50 percent of the U.S. fuel supply, mostly

as E10 and E85, cutting more than 140,000 barrels a day of foreign oil imports. In

fact, for every barrel of ethanol produced, 1.2 barrels of petroleum is displaced at

the refinery. That means more than $6.6 billion a year is staying in the U.S.

economy (Energy Information Administration). Ethanol is made from crops grown in

America, primarily corn and milo, helping sustain the American farmer. The U.S.

ethanol industry supported the creation of more than 230,000 jobs in all sectors of

the economy in 2007, adding $12.3 billion into the pockets of American consumers.

• Vehicles. Ethanol is the highest-performance fuel on the market, with an octane

rating of 113 in its pure form. Because it contains more oxygen, ethanol-enriched

fuel burns cleaner, helping to remove gummy deposits in the fuel system so engines

can run with optimal performance. Ethanol-blended fuels also burn cleaner and at a

cooler temperature, which can add to engine longevity.

For more information, please visit www.drivingethanol.org.

Sources include: the Ethanol Promotion and Information Council, the Renewable Fuels Association, the Clean Fuels

Development Coalition and the Energy Information Administration.

About ICM, Inc.

ICM, Inc., a privately-held company headquartered in Colwich, Kan., engineers, builds, and

supports renewable fuels biorefineries around the world. The company’s founders have

been trailblazing the processing of ethanol since the 1970s – receiving the first commercial

fuel ethanol manufacturing permit issued by the U.S. Bureau of Alcohol, Tobacco, and

Firearms. ICM was founded in 1995 by Dave Vander Griend and a small team of talented

engineers and skilled craftsmen who shared the core belief that, in the ethanol industry,

things could be done more efficiently, safer, and with greater returns. Backed by the

strength of hundreds of employees, ICM is focused on sustaining agriculture through

innovation. ICM is the ethanol industry’s leading technology provider, behind more than

four billion gallons of ethanol production per year, nearly half of the existing U.S. production

capacity. Additionally, ICM has spurred the development of an extensive research and

development department – continuously testing and retesting to refine process efficiencies –

and the company’s top scientists also are exploring economically-feasible, cellulose-based

ethanol production processes. For more information, please visit www.icminc.com.

# # #

Food AND Fuel is a trademark of ICM, Inc.

ICM, Inc. Guarantees Food AND Fuel Production in 2010

Biorefineries Investing in New Technology Able to Commercially Produce in Two Years

COLWICH, Kan. – June 16, 2008 – ICM, Inc. today announced that ethanol biorefineries

investing in the company's new, proprietary and innovative technology before the end of

this year, will be capable of commercially producing both food and fuel in 2010. The

announcement was made during ICM’s customer meeting at the annual Fuel Ethanol

Workshop (FEW) in Nashville, Tenn.

“We are talking about the ‘ethanol biorefinery of the future’…and very near future at that,”

said Dave Vander Griend, founder, president and CEO. “Fifty years ago, the U.S. fed the

world. We will be able to do that again with a food supply brought about by the evolution of

ethanol production.”

Since the company’s founding, ICM’s mission has been to sustain agriculture through

innovation. Recently, the company’s mission expanded to researching ways to deliver

much-needed protein to the world, by way of ethanol processing. At the same time, the

corn-to-ethanol industry is maturing, and a changing economic outlook is prompting

existing biorefineries to explore means of maintaining financial success in challenging tightethanol,

high-corn price markets. ICM recognized this changing outlook and is delivering on

its mission by developing technology to create "new renewables" that can be built upon the

existing ethanol biorefinery – the key facilitator of the new technology is a process called

dry fractionation.

Vander Griend says dry fractionation, the first component of ICM’s new six-part Food AND

FuelTM technology package, can be installed as early as the fourth quarter of this year, with

production coming on line in the second quarter of 2009.

After cleaning and moisture conditioning, the proprietary dry fractionation process

mechanically separates the corn kernel into its three main components: endosperm (the

starchy portion comprising most of the inner kernel), germ (the protein- and oil-rich center)

and bran (the kernel’s fibrous outer layer). More than just producing ethanol, optimizing

the whole kernel in this way allows for the production of a host of food-grade and feedgrade

co-products, as well as another alternate fuel source to power the process.

In addition to new food-processing capabilities, ICM’s new technology offering also provides

several other advantages for biorefineries:

• a guaranteed increase in ethanol production capacity

• reduced natural gas consumption

• decreased enzyme usage

• a platform for emerging technologies

• a bridge to cellulosic ethanol

ICM installed their first Food AND FuelTM technology package at a biorefinery in St. Joseph,

Mo. This facility, LifeLine Foods, is the proving ground for ICM’s “ethanol biorefinery of the

future” package, which includes the technology to transform corn fiber to cellulosic ethanol.

“Our situation is a little different than that of the typical ICM customer because we were a

food processor first,” says Mike Sobetski, vice president and COO, LifeLine Foods. “Prior to

partnering with ICM, more than 70 percent of our revenue came from food production. Coproducts

such as livestock feed and germ accounted for the remaining nearly 30 percent.

Today, two-thirds of our revenue is generated by ethanol and its co-products, and higherquality

food products comprise the remaining one-third. Even with this shift, we are

generating more revenue from the-now-30-percent food production than we were with 70

percent because of the increased capacities and the synergies of the new processes brought

to us by ICM.”

Based on the implementation and output happening at LifeLine, ICM has created a

preliminary economic model to outline the adoption of the new six-part Food AND FuelTM

technology package. By opening new markets for various co-products, there is the potential

for $1 billion in additional revenue over 10 years.

“We have always believed that ethanol is part of the solution to our economic, energy and

environmental issues and this is what we are doing to make ethanol better. We can now

make food during the ethanol process, we can process ethanol in an efficient and more

environmentally-friendly way, and we can help retain more of our energy dollars in the U.S.

while creating new markets for diversified global agriculture” said Vander Griend.

About Ethanol and Ethanol Processing

Ethanol is commercially produced in one of two ways, using either the wet mill or dry mill

process. Wet milling involves separating the grain kernel into its component parts (fiber,

protein, and starch) prior to fermentation. ICM-designed plants utilize a proprietary dry mill

process, where the entire grain kernel is ground into flour. The starch in the flour is

converted to ethanol during the fermentation process, while also producing carbon dioxide

and dried distillers grains (DDGS) as co-products. The carbon dioxide can be captured

(where economics allow) so it can be marketed to the food processing industry for use in

carbonated beverages and flash-freezing applications. Distillers grains are a valuable

livestock feed.

Ethanol is delivering on its promise as a renewable fuel. It is good for American vehicles, it

is good for the environment and it is good for the American economy.

• Environment. Ethanol is a clean-burning, renewable fuel. E85, a blend of 85 percent

ethanol and 15 percent gasoline, is the cleanest burning fuel available on the market

today. The use of gasoline enriched with 10 percent ethanol, E10, reduces

greenhouse gas emissions by 12 to 19 percent compared with conventional gasoline,

according to Argonne National Laboratory. E10 also reduces carbon monoxide

emissions by as much as 30 percent

• Economy. Ethanol is blended into nearly 50 percent of the U.S. fuel supply, mostly

as E10 and E85, cutting more than 140,000 barrels a day of foreign oil imports. In

fact, for every barrel of ethanol produced, 1.2 barrels of petroleum is displaced at

the refinery. That means more than $6.6 billion a year is staying in the U.S.

economy (Energy Information Administration). Ethanol is made from crops grown in

America, primarily corn and milo, helping sustain the American farmer. The U.S.

ethanol industry supported the creation of more than 230,000 jobs in all sectors of

the economy in 2007, adding $12.3 billion into the pockets of American consumers.

• Vehicles. Ethanol is the highest-performance fuel on the market, with an octane

rating of 113 in its pure form. Because it contains more oxygen, ethanol-enriched

fuel burns cleaner, helping to remove gummy deposits in the fuel system so engines

can run with optimal performance. Ethanol-blended fuels also burn cleaner and at a

cooler temperature, which can add to engine longevity.

For more information, please visit www.drivingethanol.org.

Sources include: the Ethanol Promotion and Information Council, the Renewable Fuels Association, the Clean Fuels

Development Coalition and the Energy Information Administration.

About ICM, Inc.

ICM, Inc., a privately-held company headquartered in Colwich, Kan., engineers, builds, and

supports renewable fuels biorefineries around the world. The company’s founders have

been trailblazing the processing of ethanol since the 1970s – receiving the first commercial

fuel ethanol manufacturing permit issued by the U.S. Bureau of Alcohol, Tobacco, and

Firearms. ICM was founded in 1995 by Dave Vander Griend and a small team of talented

engineers and skilled craftsmen who shared the core belief that, in the ethanol industry,

things could be done more efficiently, safer, and with greater returns. Backed by the

strength of hundreds of employees, ICM is focused on sustaining agriculture through

innovation. ICM is the ethanol industry’s leading technology provider, behind more than

four billion gallons of ethanol production per year, nearly half of the existing U.S. production

capacity. Additionally, ICM has spurred the development of an extensive research and

development department – continuously testing and retesting to refine process efficiencies –

and the company’s top scientists also are exploring economically-feasible, cellulose-based

ethanol production processes. For more information, please visit www.icminc.com.

# # #

Food AND Fuel is a trademark of ICM, Inc.

Last edited by gpsman1; 06-16-2008 at 09:30 AM.

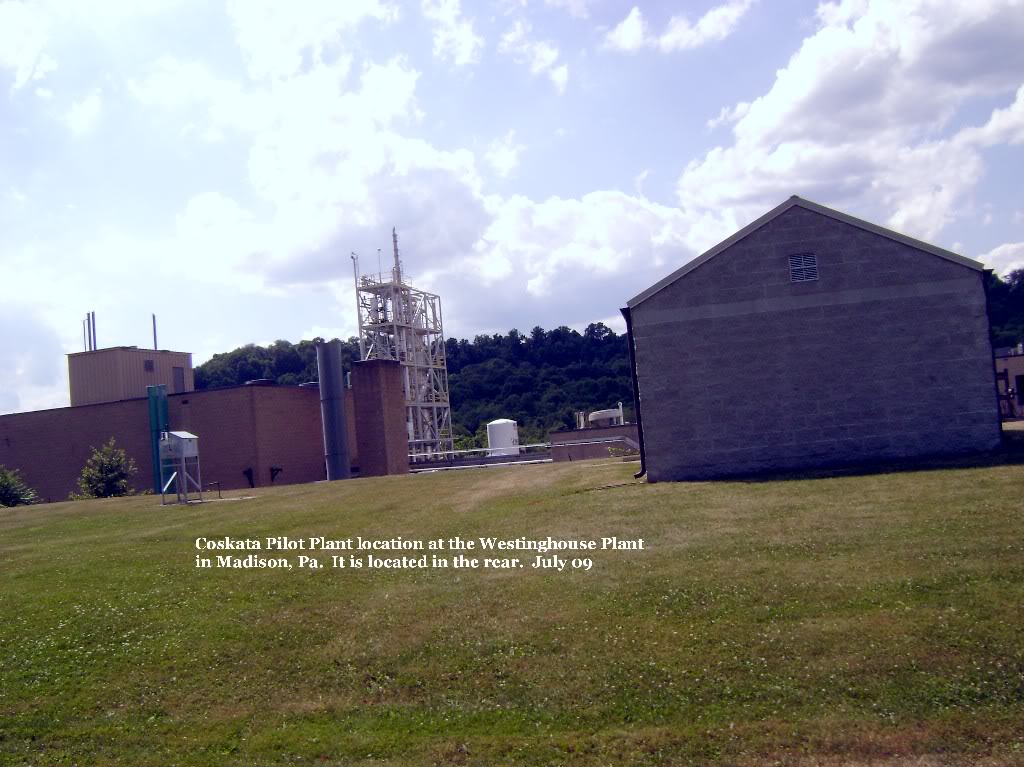

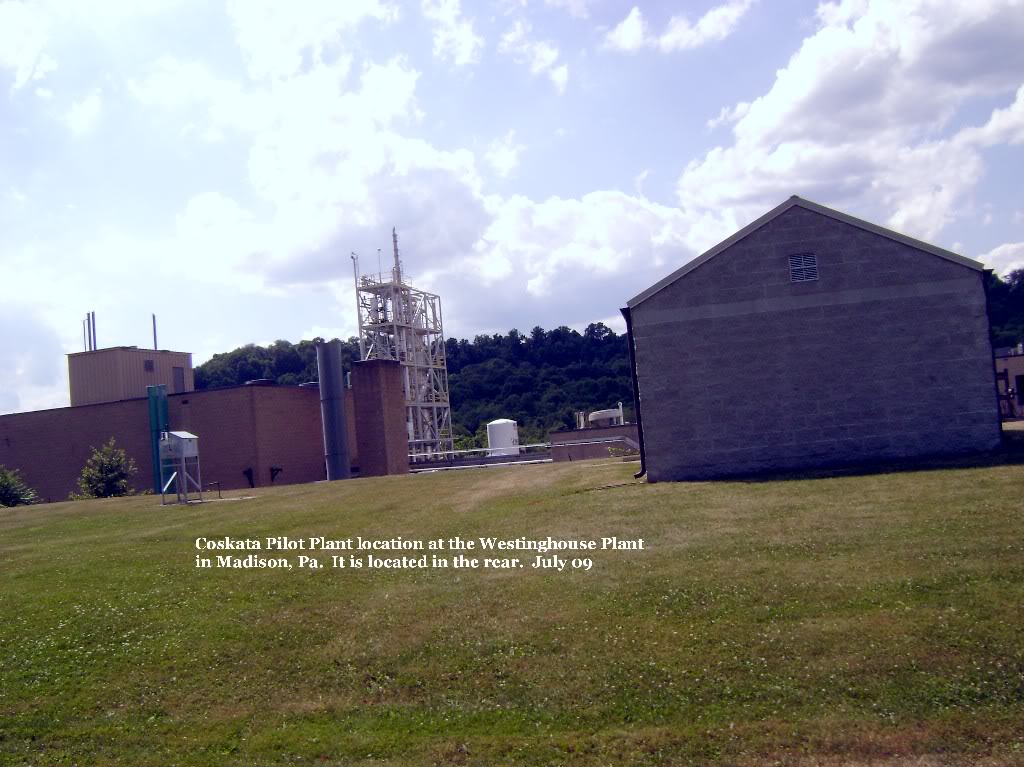

#4

The Coskata pilot plant in Madison, Pa. that makes ethanol out of any "feedstock" is up and running.

The "public announcement" for this scheduled for October 2009.

The "public announcement" for this scheduled for October 2009.

Thread

Topic Starter

Forum

Replies

Last Post

Curated Content Editor

Journalism & The Media

0

03-25-2013 05:01 PM

Curated Content Editor

Journalism & The Media

0

01-01-2013 01:31 PM

gpsman1

Alternative Fuel Vehicles

16

05-05-2010 09:54 AM

Billyk

Alternative Fuel Vehicles

0

04-26-2008 06:36 AM

Billyk

Ford Escape Hybrid

6

01-28-2008 04:09 PM